- Home

-

Products

- News

- About

- Become a Distributor

Global - English

The XAG P150 and P60 agricultural drones offer users a highly reliable solution for precise, efficient, and stable spraying operations. However, to fully unleash the drones’ capabilities, setting appropriate operational parameters and establishing proper operational practices are essential. This article provides a detailed technical guide to maximize safety, efficiency, and performance during spraying operations.

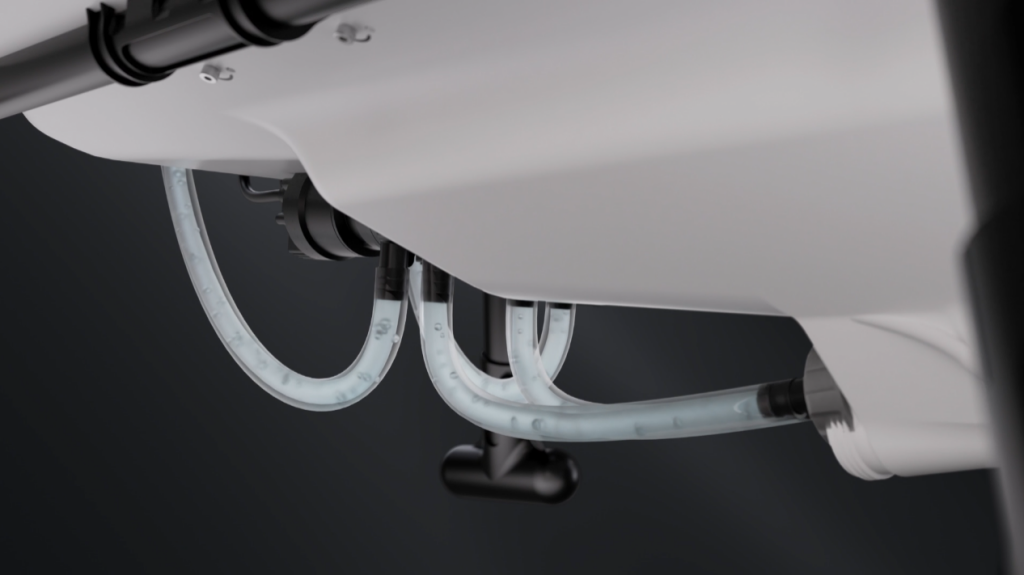

Flexible Impeller Pump Delivers Reliability and Durability

XAG P150 & P60 are using flexible Impeller pumps which are capable of handling dirty water containing sand and other particulates, allowing easy transfer of turbid liquids. They offer excellent resistance to wear, temperature, corrosion, and fracture, resulting in long service life and superior durability. The pumps are also economical and simple to maintain, where there is no need to remove pump tubes, loosen straps, or install additional complex components. Replacement only requires swapping the old impeller with a new one, a process that can be completed around 1 min.

Flexible Impeller Pump Rendering

With its combination of durability, maintenance efficiency and adaptability to complex environments, the flexible impeller pump plays a decisive role in ensuring consistent spray performance.

Priming before Spraying is Essential under Certain Circumstances

However, before performing certain spraying operations, it is necessary to carry out a priming procedure for the pump and pipes.

Priming is the process of removing air from the line by using a high flow rate to draw liquid through the system at ground level before actual spraying begins. This ensures accurate and consistent chemical output even at low flow rates, and prevents issues such as missed sprays at the start of a field, thereby ensuring continuity and precision during subsequent spraying operations. Priming is recommended in scenarios when it’s the first flight of the day, or after long breaks, or after using the drain function.

CG Demonstration of Liquid Priming the Line

For optimal results, it is advisable to use the actual spray liquid for priming. The recommended procedure is as follows:

· Add no less than 5 liters of spray liquid into the tank.

· Place a container under the spray nozzles to collect the discharged liquid. After priming, the collected liquid can be poured back into the tank for reuse to avoid waste.

· Set the flow rate to no less than 12 L/min and begin spraying.

· Stop the pump once the nozzles produce a continuous stream of liquid. Priming is considered successful when the spray is stable and the remaining tank volume is no less than 2 liters.

Once primed, the system is capable of delivering a stable, pulse-free, finely atomized spray, even at the lowest flow settings, ensuring uniform coverage at a consistent flight speed.

Optimizing Parameters for Effective Spraying

In addition to priming under specific conditions, accurate parameter settings are also critical to enhancing spraying performance.

Parameters such as flight speed, flight height, droplet size, and application rate influence the spraying performance. The correct combination of these factors allows the drone to adapt effectively to different crops and field conditions.

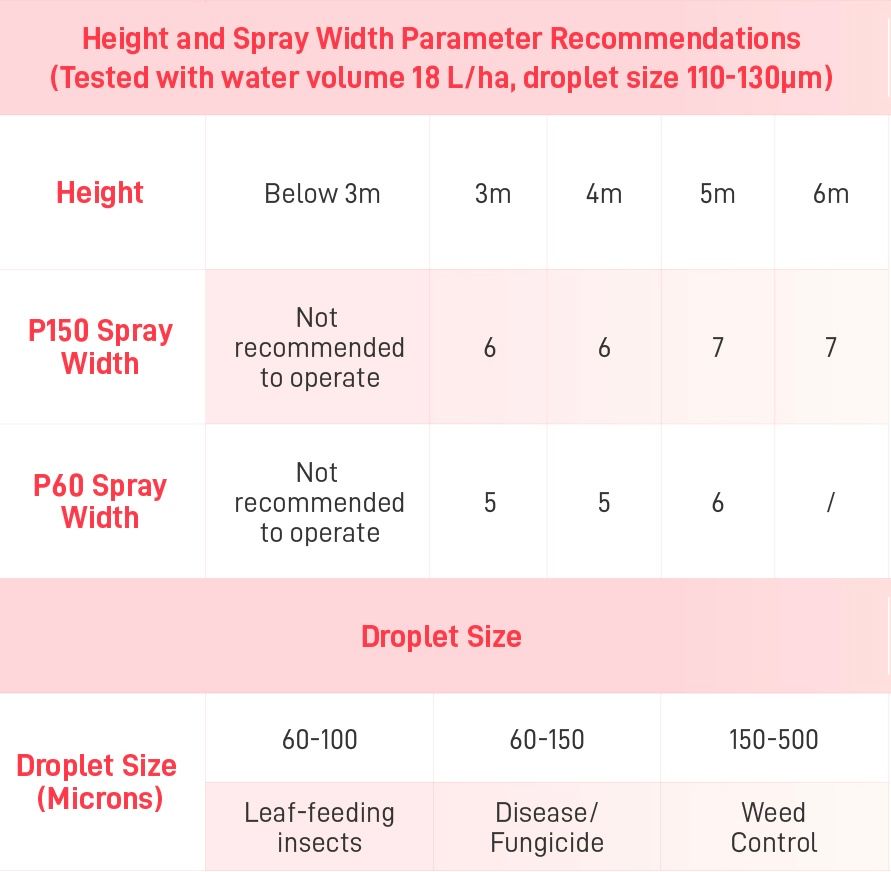

Height, Spray Width, and Droplet Size Parameter Recommendations

· When operating over crops with low plant height, the flight speed should be increased and the flight altitude raised to prevent the downdraft from causing crop lodging or physical damage.

· When working with dense crops or those with tall plant height, the application rate per hectare should be increased and the flight speed reduced to enhance spray penetration.

· When the operation height of the drone is set below 3 meters, overlap between spray nozzles may be insufficient, resulting in missed areas. As the flight height increases, the spray width becomes wider, the downdraft weaker, and the spray penetration less effective. For the P150, an operating height of 3–6 meters is recommended, with a droplet size of 110–130 μm. For the P60, an operating height of 3–5 meters is recommended, with a droplet size of 110–130 μm.

· As droplet size increases, the spray coverage area decreases, while drift resistance and evaporation resistance increase.

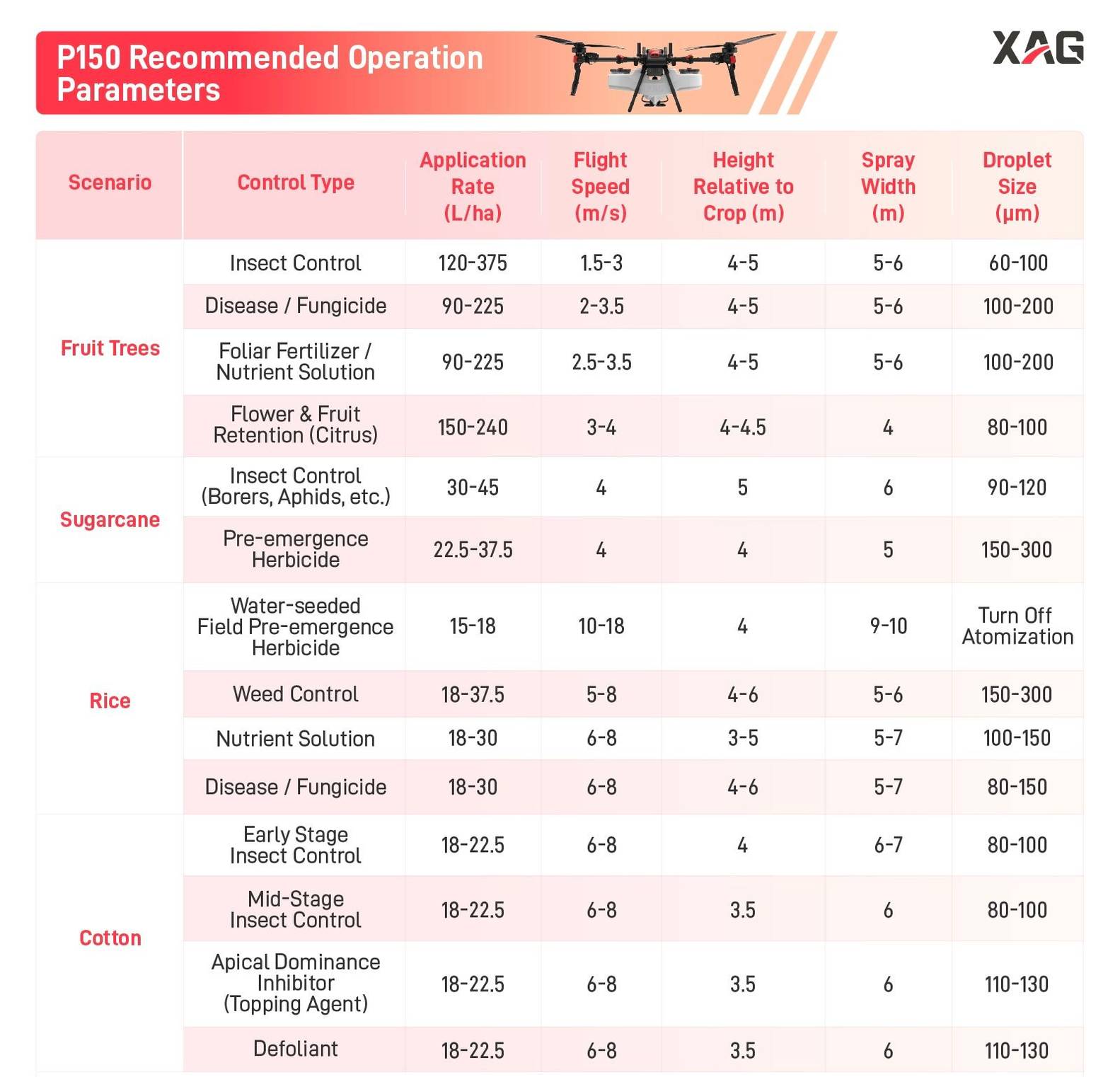

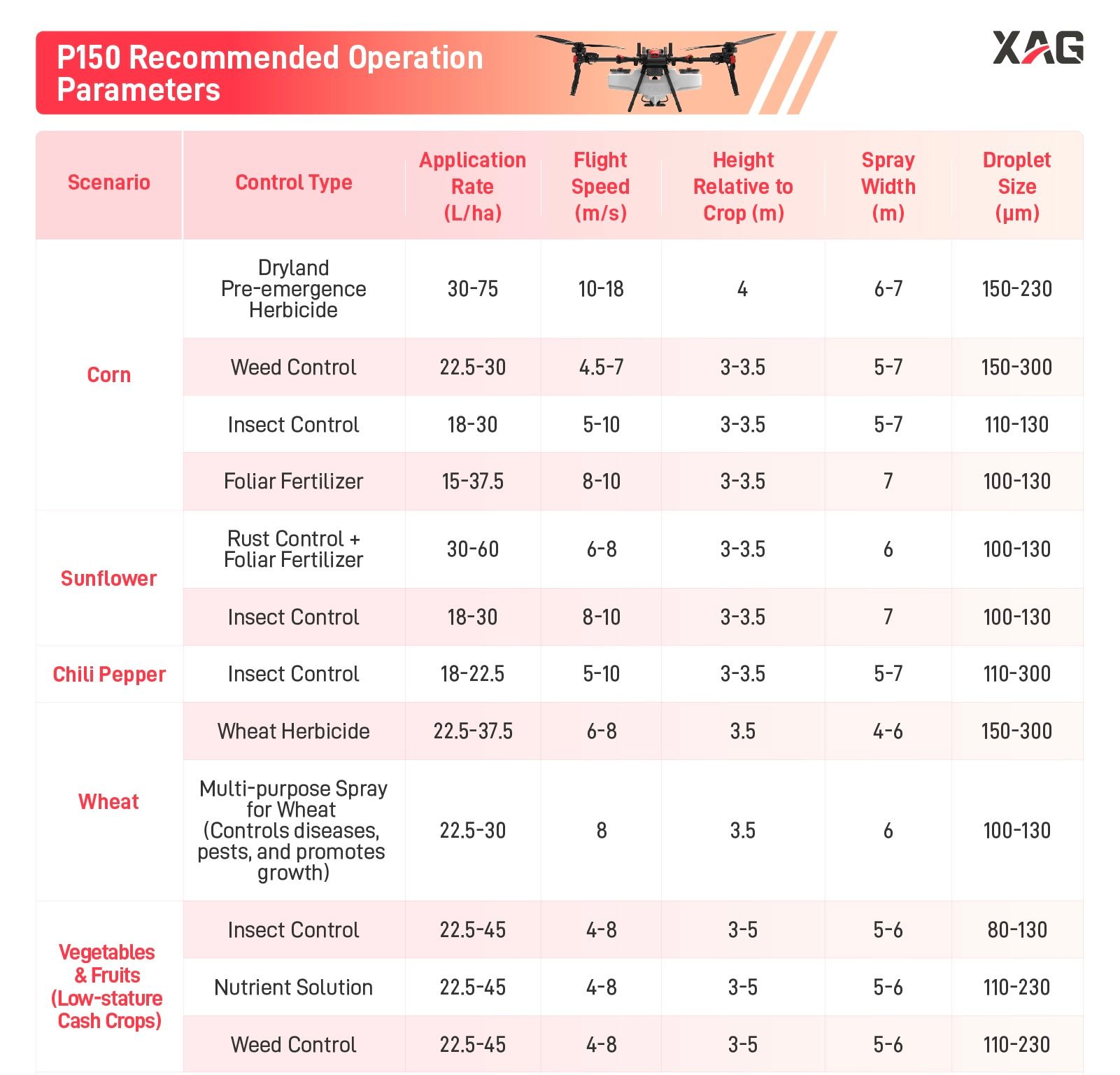

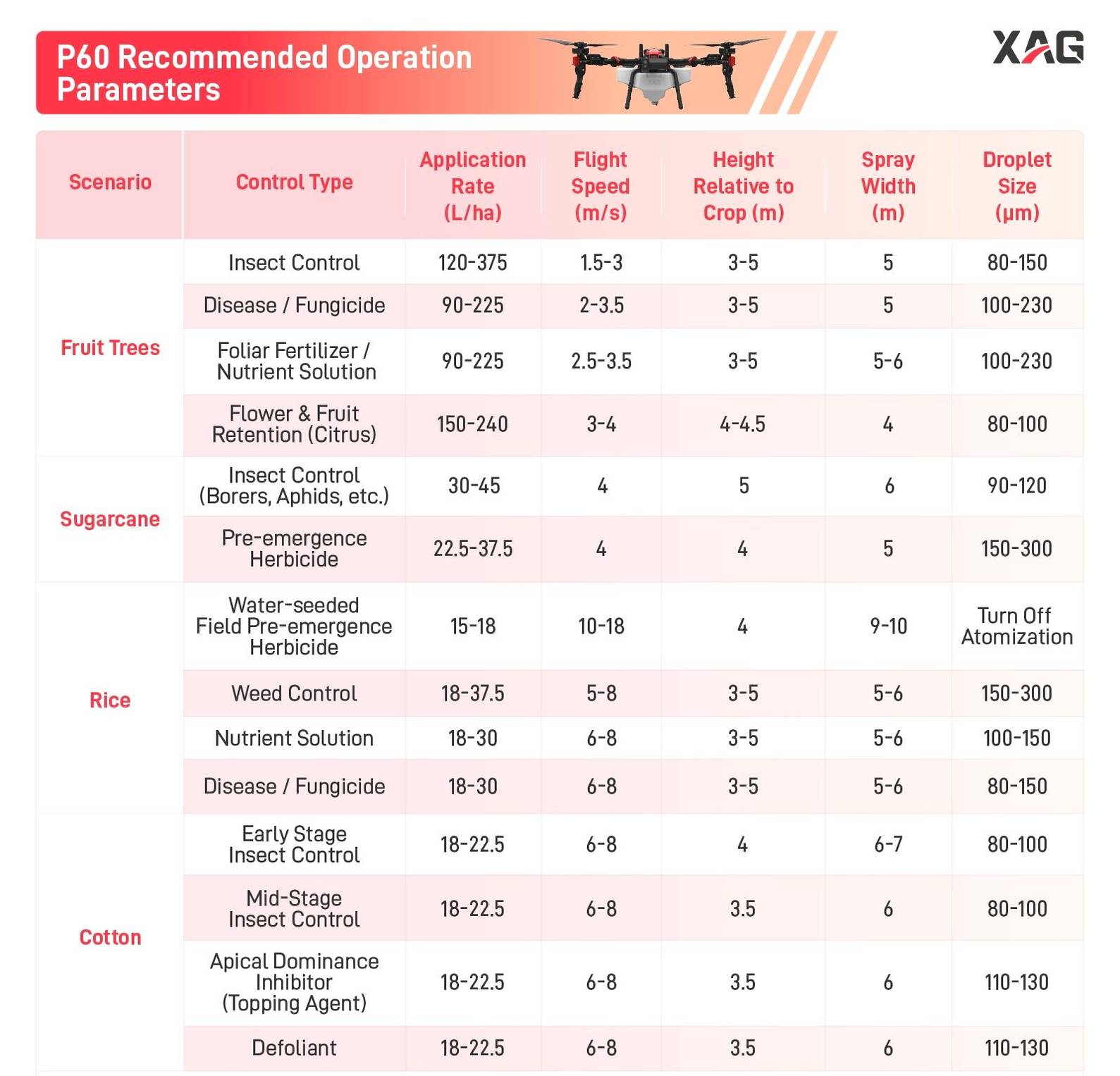

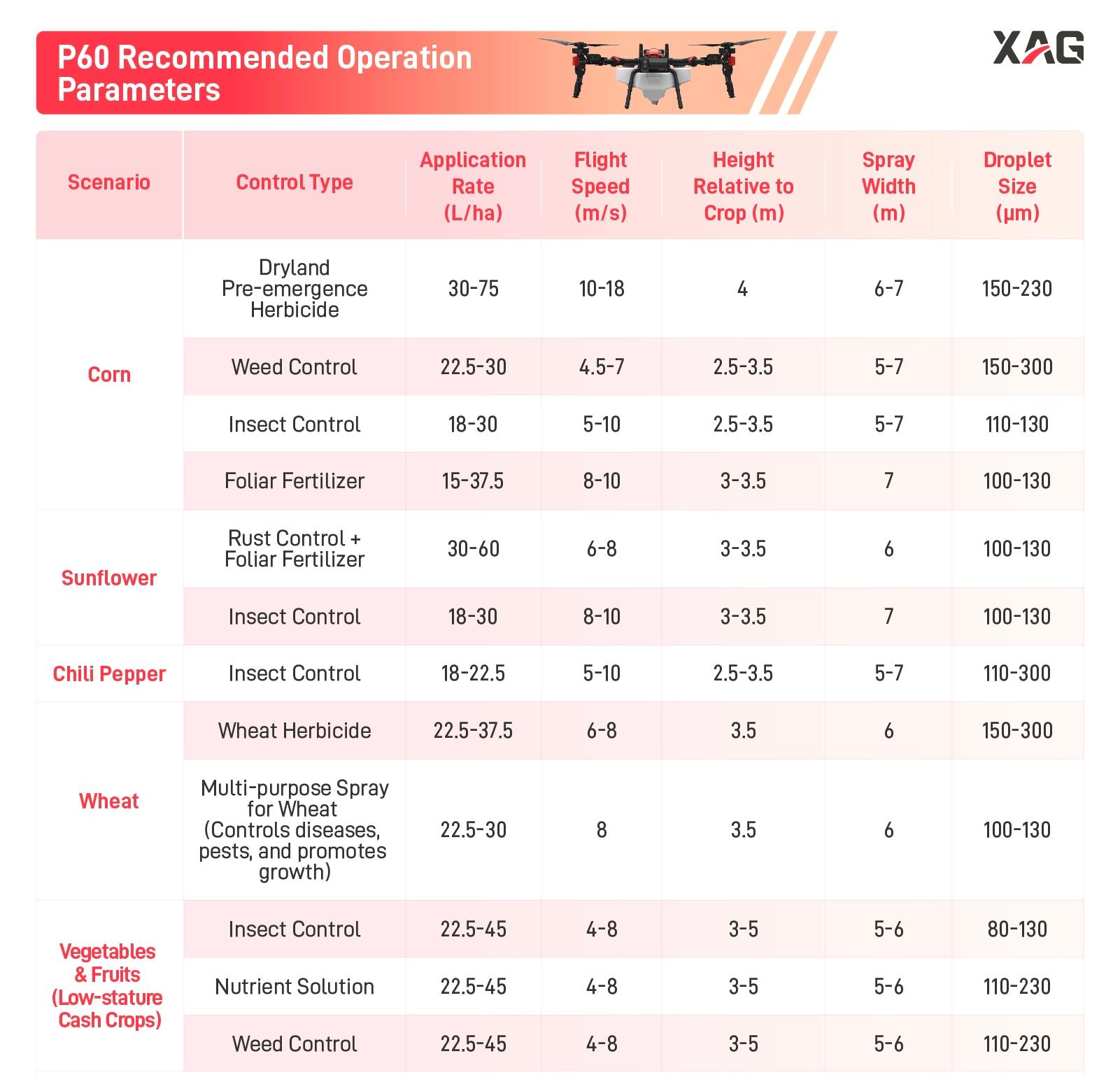

To maximize spraying efficiency, it is advised to follow recommended parameter settings tailored to different crops and specific operational conditions. These guidelines are derived from data collected by experienced drone pilots, ensuring practical reliability results.

P150 Recommended Operation Parameters

P60 Recommended Operation Parameters

· Avoid herbicide applications when wind is present to prevent spray drift.

· For pest and disease control, pay attention to the optimal treatment timing and, where possible, use tank mixtures to reduce the risk of resistance development.

· For P150, the flight height should not be lower than 3 meters. Excessive wind may cause fruit damage. When operating over dense or tall crops, increase the application rate per hectare and reduce flight speed to enhance spray penetration.

· For fruit trees with large canopy diameters and dense foliage, increase the spray flow rate appropriately and maintain a relatively low flight speed.

· When spray drift occurs, an anti-drift adjuvant may be added to the tank mixture to achieve better spraying performance.

· Ensure that the flight altitude is properly set to avoid collisions and potential accidents. When operating in orchards, pay attention to the use of both 2D and 3D operation modes. For 2D operations, the terrain-following mode should be enabled and configured accordingly.

· Since drone-applied pesticide solutions are usually of high concentration, the two-step dilution method should be followed when preparing the mixture. Foliar fertilizers such as potassium dihydrogen phosphate are recommended to be prepared separately to prevent chemical reactions that may occur in the tank mix.

In addition, the latest firmware upgrade of actuator_server 87 version for the XAG P150 and P60 enhances flow control precision and improves droplet consistency during high-speed flight. When combined with proper pipe priming and optimized parameter configurations, this upgraded system delivers superior accuracy and operational stability across a wide range of crop types and field conditions.

Effective spraying is not the result of a single component but the synergy of various factors. Together, these elements enable the XAG P150 and P60 to consistently deliver effective spraying that increases productivity, protects crops and supports sustainable agriculture.

Disclaimer:

All data in these operation recommendations are collected from experienced agricultural drone pilots. They are provided for reference only for users operating XAG P150/P60 agricultural drones for spraying operations in relevant regions.

Due to the influence of various factors such as crop growth conditions, weather conditions, and pesticide varieties, the data herein cannot fully adapt to all operational scenarios. Users should make appropriate adjustments based on actual conditions. XAG assumes no legal responsibility for this.